You will find the right components in our vast online range.

Butterfly valves

You will find in our product range lug and wafer type Butterfly valves for use in many different processes, from production off food, animalfood, cleaning agent and watertreatment to a (petro)chemical installation. And always with expert advise in connections.

VTB200 Butterfly valves

VTB300 Butterfly valves

More Butterfly valves

VAPO is a specialist butterfly valve supplier. With over 35 years of experience and a wide product range, we can provide excellent advice when selecting the right butterfly valve for your specific process. This extends beyond the type of flap and dimensions, but also looks at housing and seat materials. Of course, you can always order valves directly from our web shop. Should you need advice, our experts will be happy to assist you.

Lug or wafer butterfly valves

Within the butterfly valve category, we distinguish two main types. A lug butterfly valve has tap holes and is intended to be bolted onto the end of a pipe. A wafer butterfly valve is sandwiched between pipe flanges. An important advantage of butterfly valves is the fact that they enable control of the flow rate. This makes them perfect for controlling the medium passing through the valve. That’s why we say: “Own the flow” with VAPO.

Application of butterfly valves

Our butterfly valves can be used in a variety of processes, including food and feed production, as well as solvents, water treatment and other process installations. Butterfly valves are excellent for regulating volumes, but not particularly resistant to high pressure. As soon as pressure exceeds PN16, we recommend switching to a double or triple eccentric butterfly valve or a ball valve. However, butterfly valves are excellent for large bores. The largest butterfly valves in our range are suitable for pipes with a diameter of 1000mm.

Materials used

The housing of a butterfly valve can be made of cast iron, steel, stainless steel, aluminium, or bronze. In almost all cases, the valves are stainless steel, but they can also be bronze or aluminium. It is vital to use the correct seat, in accordance with the medium and temperature. Depending on application and medium, you can choose between EPDM, BUNA, Viton, PTFE, Hypalon, Silicone or natural rubber. For use in very harsh conditions, with high temperatures and harmful media, there are butterfly valves with Carbon/Ekono seat. The largest, most powerful butterfly valve in our range, the VTB500, has a metal seal.

Ask our experts

You can order our complete range of butterfly valves online from our web shop. If you are not entirely sure which valve is most suitable, for example when building a new installation, please ask our valve experts for support. Based on a standard questionnaire about your specific process conditions, we can tell you in detail which valve is best compatible with certain housing materials, valve, and seat. This ensures ordering the right valve straight away

Pneumatic or electric actuator of butterfly valves

All our butterfly valves are suitable for mechanical actuators and, therefore, precision adjustment. Especially with larger models, we would not recommend operating with just a handwheel, as this requires considerable force, especially in processes involving pressure or large volumes. We therefore recommend installing a gearbox or worm gearbox when using larger diameters. You can also automate the valve using pneumatic or electric actuation.

Butterfly Valve Maintenance

We regularly receive questions about butterfly valve maintenance scheduling. However, this is difficult to predict. It all depends on the process, the abrasive or corrosive properties of the medium and, of course, the frequency with which the valve opens and closes. It makes quite a difference whether this opens and closes once a month or ten times an hour. Whatever the requirement, we have overhaul kits and spare parts in stock for our best-selling butterfly valves. We can also supply parts for the less common butterfly valves, although delivery times will be slightly longer.

Certification and technical specs

We can provide all valves in the VAPO range with a 3.1 material certificate, certified in terms of material use. We offer special butterfly valves with KIWA certification for use in the drinking water supply. What’s more, we also have 3D drawings of all products in stock, available on request for machine builders and engineers.

Which butterfly valve is best for your application?

Choosing the right butterfly valve is not easy. It all depends on where the valve is required in your installation and what will be flowing through it. If you know what you need, you can order the right butterfly valve or valves straight from our web shop. Would you like advice or a second opinion from a real specialist? Don’t hesitate to contact us!

We are experts in automated valves, with ample inventory and expert advice.

Any questions about the right components for your specific application? Benefit from the expertise of our VAPO specialists: Get in contact with our advisors.

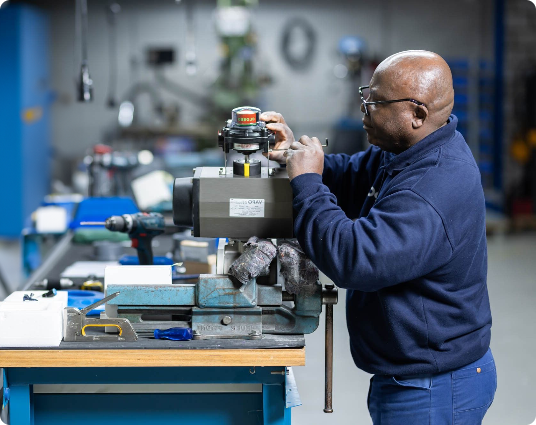

Do you need a combination of parts for your specific process? Our workshop will be happy to take care of design and custom assembly for plug-and-play installations.

Contact

Send us a message by filling in this form and we will contact you as soon as possible.